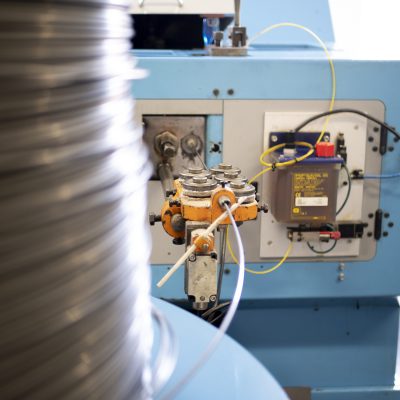

Cold heading or cold forming is a process of metal deformation in progressive steps at room temperatures.

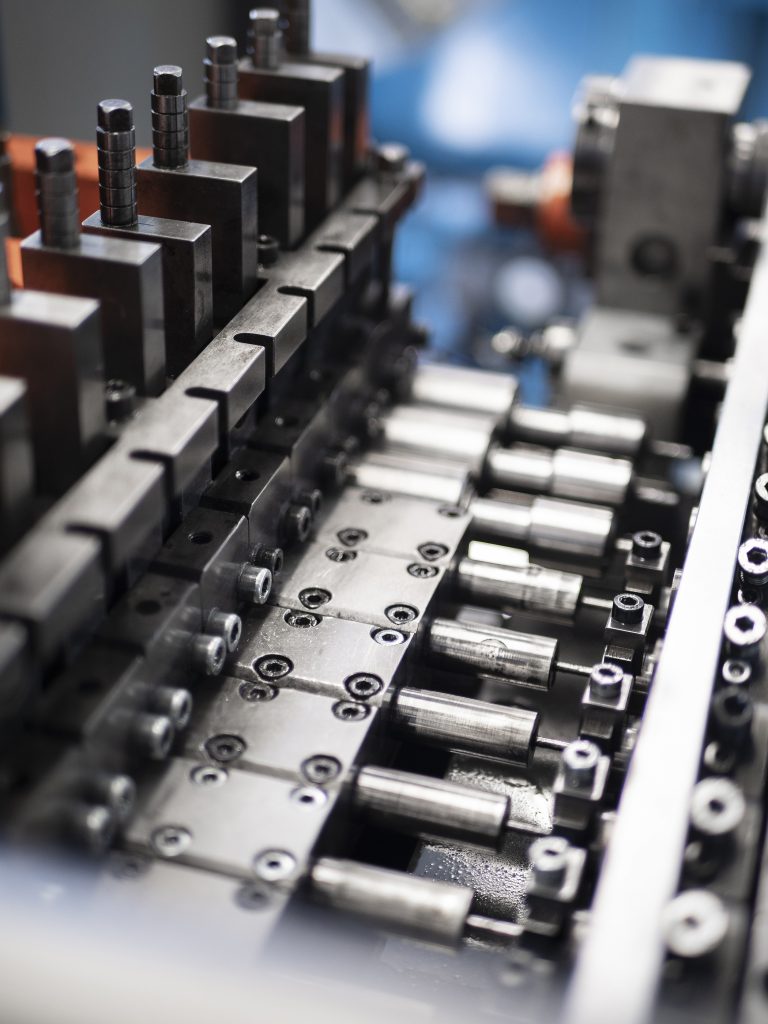

At New Microfil, we cut a blank from a continuous coil of wire that is deformed through its insertion into dies. This process is carried out by applying very high pressure which deforms the material beyond its elastic limit but without reaching its breaking point. Parts can be hit multiple times while staying in the same die or transferred from die to die for a succession of basic operations such as stamping, extrusion, reduction, trimming, piercing,…

All the operations require specific tools which are designed in order to obtained the final geometry of the product.