Quality of our products is the main commitment of our company. Our objective is to deliver 100% compliant products to each customer whatever its industry field.

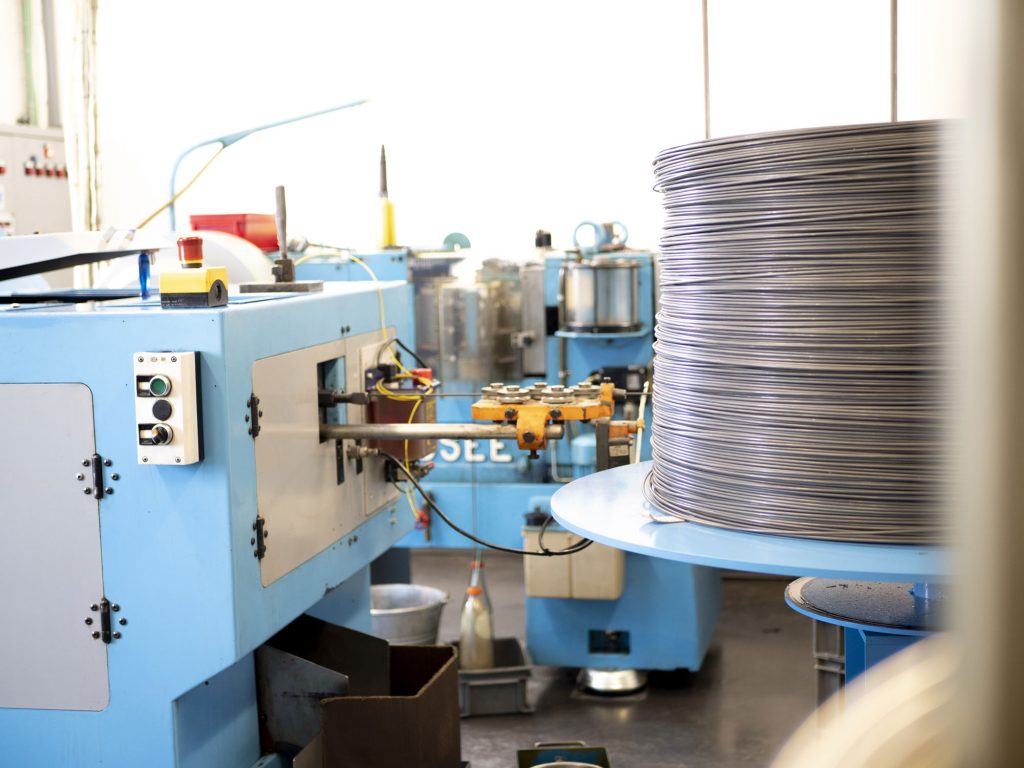

A strong Quality Management System (QMS), the purchase of high-quality raw material, the use of reliable equipment and a constant follow up of the production with a real professional consciousness from the production staff are the keys that allow New Microfil to guarantee a finished product of perfect quality.